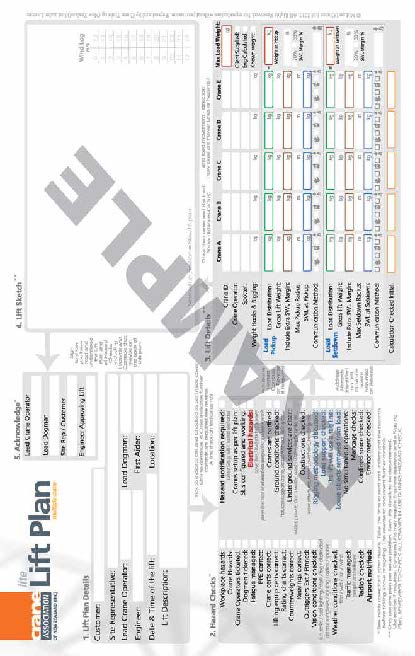

The Crane Association produces two types of Lift Plans. Single and Multi Crane.

Single Crane

The single crane lift plan is designed to address the hazards associated to cranes carrying out single crane standard lifts. The plan is available in both Lite and Standard versions.

Multiple Crane

The multiple crane lift plan is designed to address the hazards associated to multiple cranes carrying out a multi crane lift. The plan is available in both Lite and Standard versions.

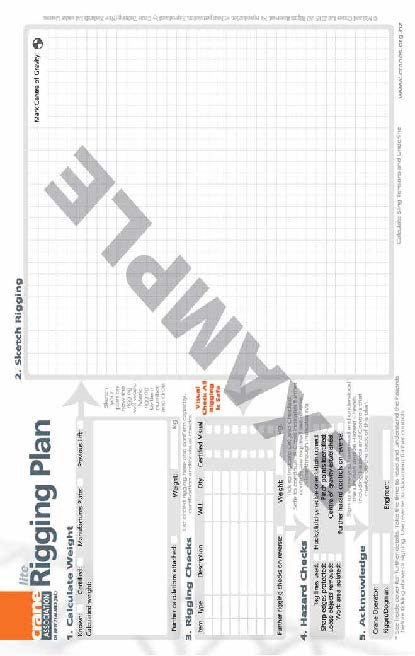

The Crane Association produces a rigging plan that can be used as standalone or as an attachment to a Lift Plan for complex lifts.

Rigging Plan

The rigging plan is designed to address the hazards associated to rigging and allows the user to create a visual representation of their plan. The plan is available in both Lite and Standard versions.

The Lift Plan Details panel identifies the parties involved in the lift and confirms:

The Hazard Checks panel lists common hazards associated to crane operation and load lifting. The complete description of each check box and its meaning is on the inside of the lift plans front cover.

Each check is a three state check box.

The hazard checks also confirm operator and dogman / rigger qualifications, and question if fatigue has been managed.

The Lift Details panel is used by the crane operator to confirm his/her calculations when planning the lift. By calculating the lift the operator must think about the pick up and set down locations and the best configuration for the crane.

The Lift Sketch panel is one of the most powerful tools used by crane operators to address hazards.

By drawing the setup location and proximity of hazards the crane operator is able to take into account the three dimensional nature of crane hazards.

Work Quadrant - Indicates area crane is working in

Wind Log - Provides an area to record wind speed

The Lift Plan Details panel identifies the parties involved in the lift and confirms:

The Hazard Checks panel lists common hazards associated to crane operation and load lifting. The complete description of each check box and its meaning is on the inside of the lift plans front cover.

Each check is a three state check box.

The hazard checks also confirm operator and dogman / rigger qualifications, and question if fatigue has been managed.

The Lift Details panel is used by the crane operator to confirm his/her calculations when planning the lift. By calculating the lift the operator must think about the pick up and set down locations and the best configuration for the crane.

The Lift Sketch panel is one of the most powerful tools used by crane operators to address hazards.

By drawing the setup location and proximity of hazards the crane operator is able to take into account the three dimensional nature of crane hazards.

Work Quadrant - Indicates area crane is working in

Wind Log - Provides an area to record wind speed

The Calculate Weight Panel provides a tool for the Rigger

to identify and calculate the weight of the lift. Whether it

be:

The Sketch Rigging panel provides a tool to be used by riggers to identify all rigging components to be used.

By drawing the rigging the rigger can confirm angles and sling tensions.

The Rigging Checks panel is used by the Rigger to confirm checking each component of rigging is suitable for the lift. The rigger can also use the panel to calculate the weight of the rigging.

The Hazard Checks panel lists common hazards associated to rigging.

Each check is a three state check box.

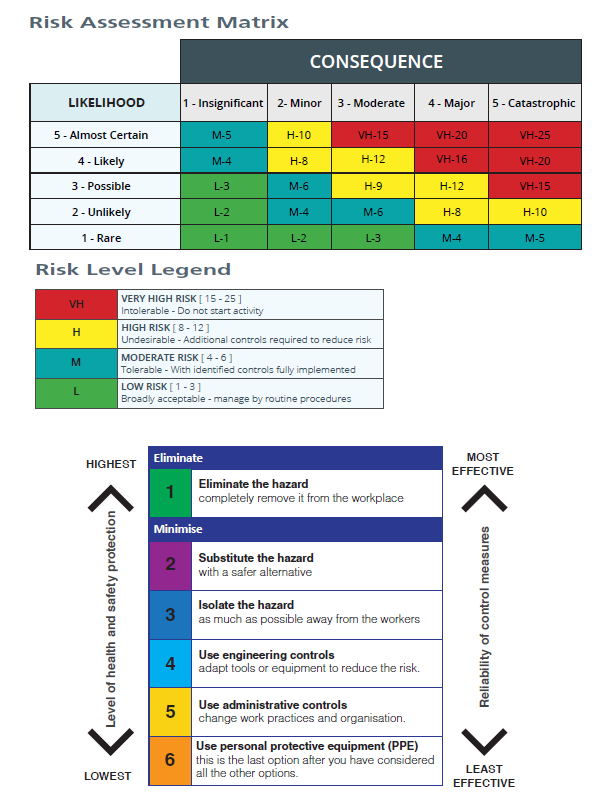

The Foreseeable Hazard the user has identified as presenting a risk to the operation.

The initial Risk associated to the Hazard before any

controls are assigned and implemented.

Risk is allocated as:

The control to be assigned and implemented to eliminate or minimise the hazard.

The type of control that is to be applied by using the

Hiararchy of Risk Control.

1. Eliminate

2. Substitute

3. Isolate

4. Engineering

5. Administration

6. PPE

The residual Risk associated to the Hazard after any controls are assigned and implemented.

Risk is allocated as:

The Role responsible for monitoring and ensuring the control is in place and working.

The levels of risk of a hazardous event occurring cover:

very low, low, moderate, high, and critical. The severity of

potential injury or illness covers:

› catastrophic

› major

› moderate

› minor

› insignificant

The Hierarchy of Controls table takes you through a logical

flow of options, from most effective to least effective, to

guide you in eliminating and minimising hazardous events.

You will need to use the Risk Assessment Matrix and the

Hierarchy of Controls table for completing the:

› Single Crane Lift Plan

› Multiple Crane Lift Plan

› Rigging Plan